STAINLESS STEEL

DISHED ENDS

AND RELATED PRODUCTS

DISHED ENDS

AND RELATED PRODUCTS

STAINLESS STEEL

DISHED ENDS

AND RELATED PRODUCTS

DISHED ENDS

AND RELATED PRODUCTS

Stainless steel dished, flat, conical and hemispherical ends

Stainless steel dished, flat, conical and hemispherical ends

F.B. INOX is a metalworking company with headquarters in Padua, Italy, specialized in the production of dished ends, flat ends, conical reducers and related components made of stainless steel. We have been operating on the Italian and global market since 1998 and our mission is to supply high quality and reliable products, constantly investing in technology and tailor made finishes. Our dished ends are the essential components of tanks, cisterns, pressure vessels, machines and high-yield processing systems. Our work is totally focused on customer satisfaction.

Why choose F.B. INOX

F.B. INOX can boast over thirty years of experience in stainless steel processing for the production of industrial use dished ends machined in compliance with the sector’s standards and specifications and guaranteed by our international certifications. Top quality, precision and fast turnaround time are our strengths. The satisfaction of our Italian and global clientele is what drives us every day to invest in technology and procedures designed to improve and optimize our products and services.

QUALITY

KNOW HOW

PRECISION

ASSISTANCE

Applications

Stainless steel dished ends for industrial tanks and pressure vessels

Stainless steel dished ends for industrial tanks and pressure vessels

For over 20 years we have been specializing in the manufacture of dished ends for tanks, reactors and industrial containers made of stainless steel. Our torispherical, conical and hemispherical ends are used for the construction of containers made to guarantee the absence of contamination or of imperfections during industrial processes such as mixing, condensation, drying and conservation of chemical and/or pharmaceutical components and for the agro-food industry. Stainless steel pressure tanks and vessels are also used for the production, fermentation and conservation of wine and beer.

For over 20 years we have been specializing in the manufacture of dished ends for tanks, reactors and industrial containers made of stainless steel. Our torispherical, conical and hemispherical ends are used for the construction of containers made to guarantee the absence of contamination or of imperfections during industrial processes such as mixing, condensation, drying and conservation of chemical and/or pharmaceutical components and for the agro-food industry. Stainless steel pressure tanks and vessels are also used for the production, fermentation and conservation of wine and beer.

Pharmaceuticals

Agro-foods

Chemicals

Cosmetic

Wine

Beer

Most popular products

News

DISHED ENDS UP TO 20 MM THICK

Thanks to the purchase of a new flanging machine, we are now capable of producing ends up to 20 mm thick and ellipsoidal ends with diameter up to 4 metres. This new machine also allows us to make dished ends with or without a central hole.

SUSTAINABLE PRODUCTION

We have installed a photovoltaic system on our factory roof in order to contribute to the use of non-polluting energy, because we are continuously committed to protecting the environment and to preserving it for future generations.

IMPROVED DISHED END MANUFACTURING PROCESS

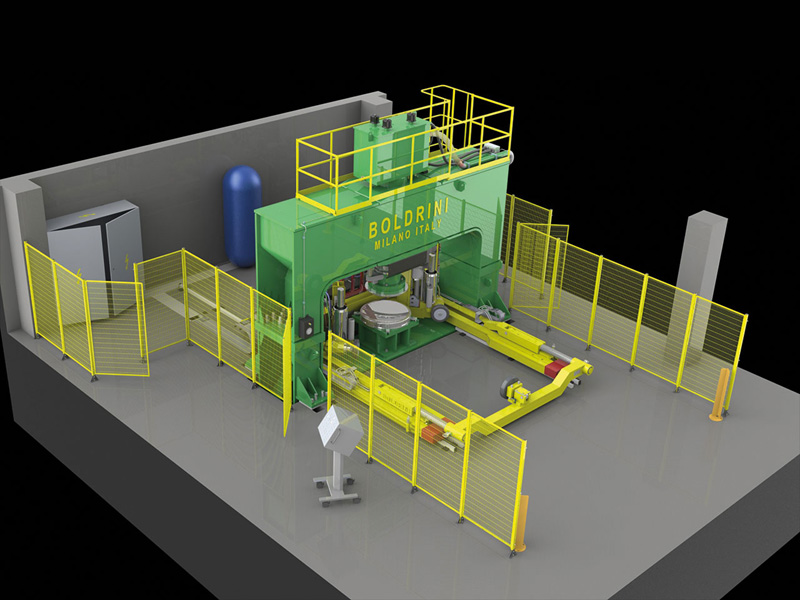

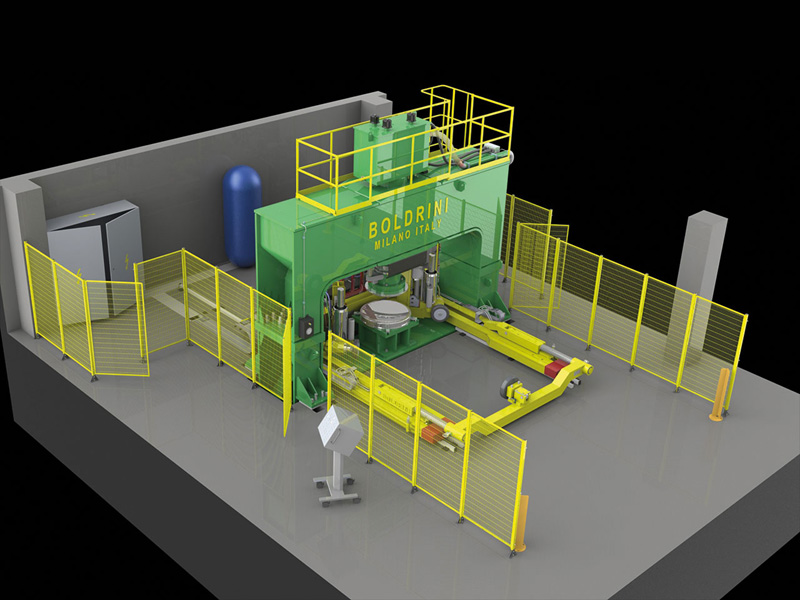

We have purchased a new 400 ton press for dishing spherical ends. The system is equipped with a manipulator specifically designed to spin the disks faster and therefore speed up processing time.

News

ENDS UP TO 20 MM THICK

Thanks to the purchase of a new flanging machine, we are now capable of producing ends up to 20 mm thick and ellipsoidal ends with diameter up to 4 metres. This new machine also allows us to make dished ends with or without a central hole.

SUSTAINABLE PRODUCTION

We have installed a photovoltaic system on our factory roof in order to contribute to the use of non-polluting energy, because we are continuously committed to protecting the environment and to preserving it for future generations.

NEW DISHING SYSTEM

We have purchased a new 400 ton press for dishing spherical ends. The system is equipped with a manipulator specifically designed to spin the disks faster and therefore speed up processing time.

Certifications

ISO 9001

Quality Management System

2014/68 EU (PED)

PED Directive, Annex I, 3.1

Manufacturing Procedures

EN ISO 3834-2

Quality requirements for fusion

welding of metallic materials

AD 2000-Merkblatt HP0

Construction and testing

of pressure equipment